Tags

Business Partner, IM, MATDOC, Materials Management, MM, P2P, PortSAP, Ray Hornbrook, SAP, SAP MM, SAP P2P

What is SAP Materials Management (MM)?

SAP Materials Management (MM) is the part of SAP ERP and SAP S/4HANA that runs procurement, inventory management, and logistics invoice verification. MM helps a company buy what it needs, keep the right stock on hand, and pay accurate invoices on time—with traceable postings to finance. Think of it as your operational backbone for procure-to-pay (P2P): fewer surprises in spend, better stock visibility, and cleaner month-end.

MM is not Accounts Receivable (that’s FI-AR). Invoices that MM touches are vendor invoices, which post to FI-AP after Logistics Invoice Verification (LIV).

Where MM Fits (FI, SD, PP, WM/EWM, QM)

MM integrates tightly with other core components:

- FI (Financial Accounting): LIV posts to Accounts Payable with the right tax and price conditions.

- SD (Sales & Distribution): Outbound goods issues and returns align with stock and valuation in MM.

- PP (Production Planning): Components are staged to production; receipts of finished goods update inventory and valuation.

- WM/Stockroom Management/EWM: Bin-level warehouse execution; MM handles the legal/financial goods movement.

- QM (Quality Management): Inspections and usage decisions can influence stock status and movement.

In S/4HANA, you’ll also see structural shifts: classic vendor master gives way to Business Partner, and inventory line items post to MATDOC instead of ECC’s MSEG/MKPF.

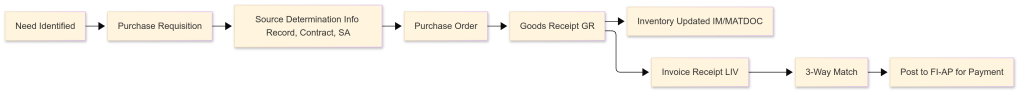

Procure-to-Pay (P2P) at a Glance

- Need identified → create a Purchase Requisition (PR).

- Source determination → Contract, Scheduling Agreement (SA), Purchasing Info Record, Source List or a new Quote.

- Convert to Purchase Order (PO) and send to the vendor (EDI/email/portal).

- Goods Receipt (GR) → stock and valuation update (in S/4HANA via MATDOC).

- Invoice Receipt (IR) / LIV → match invoice to PO (and GR) for a 3-way match.

- On a successful match, the system posts to FI-AP for payment according to terms.

This flow enforces pricing discipline, improves service levels, and keeps financial audit trails tight.

Key Master Data You’ll Actually Use

- Material Master: What you buy, stock, and plan—units of measure, valuation class, MRP views, storage data.

- Business Partner (Vendor): Banking, payment terms, partner functions—replaces classic vendor in S/4.

- Purchasing Info Record (PIR): Vendor-material specifics: prices, lead times, tolerances.

- Source List / Quota Arrangement: Preferred and split sourcing rules.

- Contracts & Scheduling Agreements: Long-term commercial frameworks; SAs carry delivery schedules.

- Organization Units: Plant (core unit for production/procurement/inventory), Storage Locations under the plant, Purchasing Org/Group for buying.

Purchasing Basics (and How “Pricing Procedure” Really Works)

Purchasing turns demand (PR) into supply (PO) with the right source and conditions. In MM, the pricing procedure is called a calculation schema—a sequence of condition types that build the net price: base price, surcharges/discounts, freight, and taxes. Access sequences determine how the system finds the right condition records (e.g., contract price vs. info record). You can tailor schemas by purchasing organization, document type, or vendor schema group to enforce policy and negotiated rates.

Scheduling Agreements shine when you need recurring deliveries with firm/forecast schedules. Contracts govern pricing and terms but don’t carry delivery schedules.

Inventory Management (IM) Without the Jargon

Inventory Management records the legal and financial side of stock movements:

- Goods Receipt (GR): Into unrestricted or quality inspection.

- Goods Issue (GI): To production, cost centers, or sales.

- Transfers: Between storage locations or plants; stock type changes (e.g., blocked → unrestricted).

- Adjustments & Physical Inventory: Count, reconcile, and post differences.

In S/4HANA, everything posts to MATDOC, a single line-item table that simplifies reporting and eliminates legacy aggregates. If you also run WM/Stockroom/EWM, those layers orchestrate bin-level execution while IM handles the quantity/valuation posting.

Logistics Invoice Verification (LIV)

LIV is where vendor invoices are checked and posted:

- Match invoice ↔ PO (and usually ↔ GR) to catch price/quantity variances.

- Blocked invoices route for resolution; tolerances prevent noise from minor rounding.

- A posted invoice creates logistics documents and an FI document, hitting AP with the right GL, tax code, and cost object.

The payoff: fewer overpayments, clearer accruals, and better cash planning.

Batch Management (When Traceability Matters)

Activate Batch Management for materials with traceability, shelf life, potency, or grade. Each batch carries attributes (e.g., expiration date), flows through procurement and inventory, and can integrate with QM for inspections. Batch determination during GI/production ensures the right lots go to the right orders, which is key in regulated or high-mix environments.

Benefits Leaders Actually Track

- Spend discipline: Contract pricing and three-way match reduce leakage and maverick spend.

- Service levels: Better stock accuracy → fewer line-stops and backorders.

- Working capital: More reliable GR/IR, cleaner accruals, and earlier capture of cash discounts.

- Cycle time: Less manual rework from PR to payment.

- Auditability: End-to-end traceability from PO through FI postings.

- Analytics: In S/4, MATDOC and embedded analytics speed variance analysis and close.

KPIs to watch: PO price adherence, GR/IR aging, invoice first-pass yield, stock accuracy, turns, and on-time in-full (OTIF).

FAQs

Is MM the same as Warehouse Management?

No. MM posts the legal/financial movement. WM/Stockroom/EWM manages where stock sits and how it’s moved inside the warehouse.

Does MM handle receivables?

No. MM integrates with FI-AP (vendor payables). Customer receivables are FI-AR.

Do I need Batch Management for every material?

Only when you need traceability or shelf-life/grade control.

What changed in S/4HANA for inventory?

Line items post to MATDOC, simplifying reporting versus ECC’s MSEG/MKPF.

What’s a Plant in MM terms?

An SAP organizational unit for procurement/production/inventory. Storage Locations belong under a plant.

Where do taxes/freight get calculated on a PO?

In the calculation schema (pricing procedure) via condition types (e.g., freight, tax, discounts).

Simple Procure-to-Pay Diagram

Next Steps (Adoption Tips You Can Use This Quarter)

- Tidy master data first. Small fixes (units of measure, valuation class, purchasing groups, lead times) pay big dividends in P2P accuracy.

- Lock in pricing governance. Use contracts/SAs and the right calculation schema to prevent “one-off” pricing.

- Standardize tolerances. Right-size invoice/quantity tolerances to reduce false blocks without letting real issues slip through.

- Pilot Batch Management where it matters. Start with a limited, high-value or regulated subset of materials.

- Measure relentlessly. Track GR/IR aging, first-pass invoice rate, and PO price adherence; review exceptions weekly.

- Plan the S/4HANA path. Map where Business Partner and MATDOC change your reporting and integrations; target quick wins with embedded analytics.

Bottom Line

SAP MM gives operations and finance a shared, trustworthy view of spend and stock. When the PR → PO → GR → IR chain is clean, you protect margins, keep lines running, and close the books faster—with less firefighting. If you’re starting fresh, stabilize master data and pricing governance first; then layer on batch controls, analytics, and warehouse execution as your maturity grows.

If you have question on this or any other PortSAP Consulting blog please feel free to contact us at Blog@PortSAP.com. Or if you are looking for Top Quality SAP Consultants please feel free to contact us.

The author, Ray Hornbrook, has over 19 years of SAP functional and technical experience. Ray started his career in SAP as a MM/PP Subject Matter Expert (SME) for a SAP implementation in 1998 and is now a Senior Level SAP Consultant. Since Ray has worked both sides of SAP, business end user and IT professional, he is able to communicate effectively with both IT and Business team members. Having a background as an SAP business end user has helped Ray greatly in his consulting career. The business background helps him better communicate with the business members of the team. As well as helping bridge gaps in communication between the IT and Business team members.

To find out more about Ray Hornbrook please check out his LinkedIn profile by clicking HERE.

End of document – www.portsap.com

You must be logged in to post a comment.